Application: Concrete-Bolt-On

Application: Concrete-Bolt-On

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Thru-Bolt W/Back Plates |

|

Application: |

Concrete |

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Thru-Bolt W/Tube Steel |

|

Application: |

Concrete on Pan Deck |

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Thru-Bolted |

|

Application: |

Concrete Joist |

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Undercut Anchor |

|

Application: |

Concrete |

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Hilti Kwik Bolt – Stainless |

|

Application: |

Concrete |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Bolt-on to CIP-Cage |

|

Application: |

Concrete |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-81, Series |

|

Fastener Type: |

Thru-Bolt W/Back Plates |

|

Application: |

Concrete |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-81, Series |

|

Fastener Type: |

Undercut Anchor |

|

Application: |

Concrete |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-81, Series |

|

Fastener Type: |

Hilti Kwik Bolt – Stainless |

|

Application: |

Concrete |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-81, Series |

|

Fastener Type: |

SST HAS Rods / RE500 Epoxy |

|

Application: |

Concrete |

|

Anchor Type: |

8-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

SST HAS Rods / RE500 Epoxy |

|

Application: |

Thin Concrete Slabs |

|

Anchor Type: |

8-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Hilti Kwik Bolt – Stainless |

|

Application: |

Thin Concrete Slabs |

Application: Steel Mounted

Application: Steel Mounted

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Wrapped Joist |

|

Application: |

Steel – Bolt-Around |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-81, Series |

|

Fastener Type: |

Thru-Bolted |

|

Application: |

Steel – Bolt-Thru |

|

Anchor Type: |

2-Bolt Pattern |

|---|---|

|

Model Number: |

SM-81, Series |

|

Fastener Type: |

Wrapped Around Tube |

|

Application: |

Steel – Bolt-Around |

|

Anchor Type: |

Eye & Tube Extension |

|---|---|

|

Model Number: |

SM-4-0, Series |

|

Fastener Type: |

/ |

|

Application: |

Steel – Weld-On |

|

Anchor Type: |

4-Bolt Pattern |

|---|---|

|

Model Number: |

SM-1, Series |

|

Fastener Type: |

Wrapped Steel Beam |

|

Application: |

Steel – Bolt-Around |

Application: Concrete – Cast in Place

Application: Concrete – Cast in Place

|

Anchor Type: |

4-Stud Pattern |

|---|---|

|

Model Number: |

SM-5, Series |

|

Fastener Type: |

Nelson Studs |

|

Application: |

Cast in Place |

|

Anchor Type: |

Eye, Tube, & Base |

|---|---|

|

Model Number: |

SM-6, Series |

|

Fastener Type: |

Single Plate |

|

Application: |

Cast in Place |

|

Anchor Type: |

2-Stud Pattern |

|---|---|

|

Model Number: |

SM-85, Series |

|

Fastener Type: |

Nelson Studs |

|

Application: |

Cast in Place |

Roof & Wall Anchors

Roof and Wall Anchors Manual

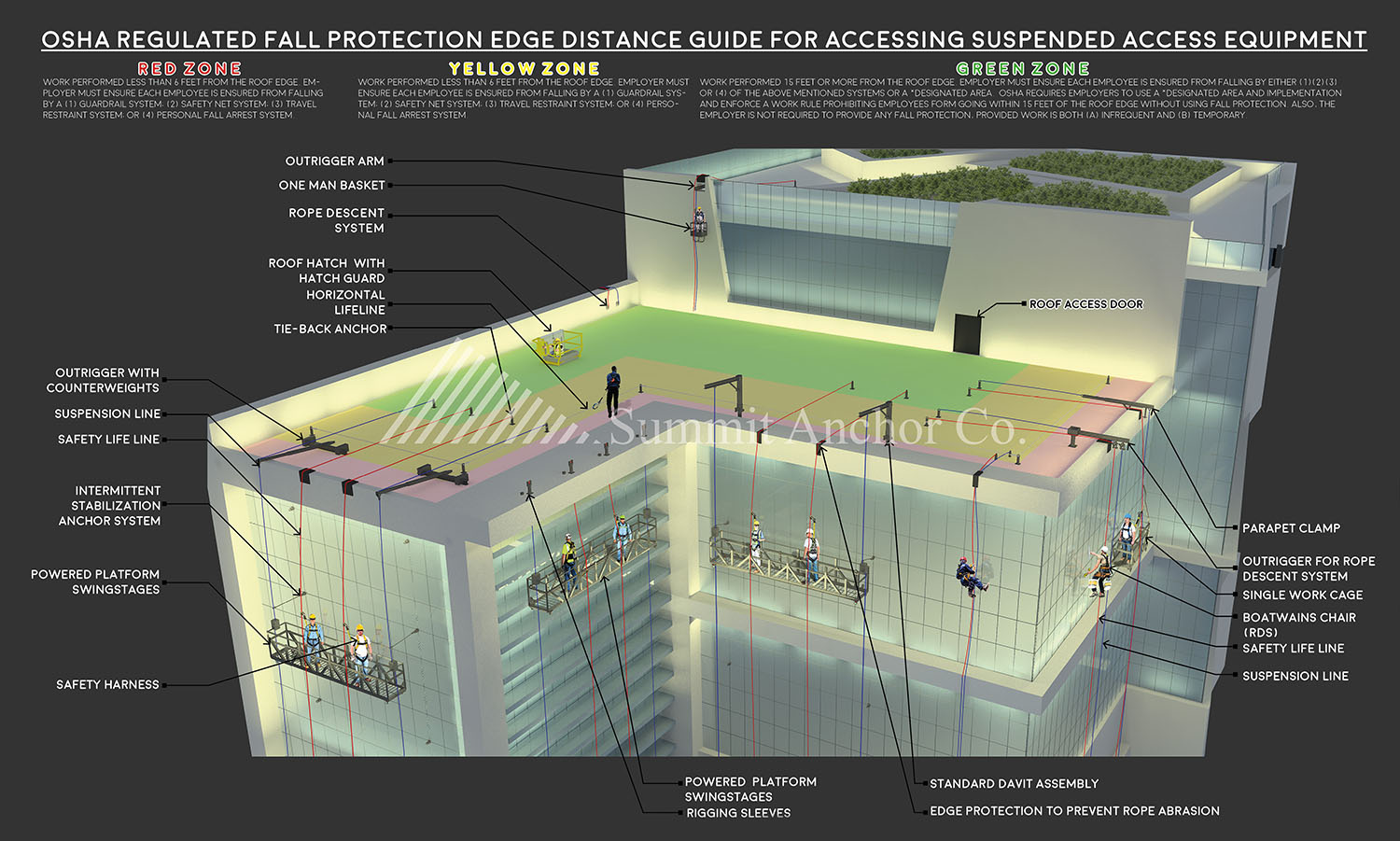

- Anchorage Layout Guidelines for Rope Descent Systems

- Anchorage Layout Guidelines for Fall Protection Systems

- Anchorage Layout and OSHA Subpart D Walking and Working Surfaces compliance

- Anchorage Connection Details – Concrete and Steel

Roof and wall anchors are the simplest means of ensuring the safety of maintenance contractors who must work on the building face. Although roof and wall anchors alone may not satisfy all of the requirements of the structure, when properly designed and installed, they can play a vital role in achieving compliance with OSHA requirements and ANSI/IWCA I-14.1 standards.

Why Specify Summit Anchor Co.

Summit’s trademark roof anchors are the #1 selling product for our company!! Here’s why:

- Our anchors have been engineered and tested to comply with current OSHA regulations

- Anchor manufactured in the U.S.A. *

- Corrosion resistance Our anchors are completely hot-dipped galvanized with stainless bolts.

- Standard design, Summit’s anchors are designed for a variety of permanent applications to reinforced concrete or structural steel. Summit standard design anchors for a variety of concrete strengths and thicknesses that can be installed onto any adequate structure.

- Consultations for architects and engineers throughout the complete design cycle on anchor layout and compliance issues.

A trademark eye is drop forged then quenched and tempered. The tremendous compressive forces involved in drop forging along with the careful heat-treating and cooling process result in an anchor that is stronger than a non-forged anchor. **

The additional quench-and-tempering process of Summit’s anchor eyes ensures consistent performance of all of our anchors. The heat treatment and cooling process capitalizes on the properties of the steel to create anchor eyes with reduced risk of catastrophic failure due to brittleness and with the toughness to withstand critical suspended access application, literally when a worker’s life is on the line.

* Refers to final assembly of parts, including welding and hot-dipped galvanizing, but may not apply to individual assembly parts some of which may not be domestic.

** According to the Forging Industry Association: “Forgings have grain oriented to shape for greater strength. Machined bar and plate may be susceptible to fatigue and stress corrosion because machining cuts material grain pattern. In most cases, forging yields a grain structure oriented to the part, resulting in optimum strength, ductility, and resistance to impact and fatigue.”

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Overview

United States and Canadian national safety standards require building owners’ to provide certification that their anchorages are certified capable of supporting 5,000 load before rope descents work is performed.

Roof and wall mounted anchorages are the simplest way to equip a building for fall protection and suspended access.

Safe accessibility to all architectural features require more then anchorages, but, has provided OSHA Subpart D, and CAN/CSA Z91 compliance for many buildings.

Anchorages can be used for as part of the following:

- Rope descent systems

- Portable outriggers beam systems

- Fall restraint systems

- Fall arrest systems

Summit Anchor Company can provide anchorage that will facilitate whatever exterior maintenance might be required on our building. Some common examples of this type of maintenance are:

- Construction

- Window cleaning

- Waterproofing, caulking and façade cleaning

- Façade roof renovations, window replacement

- Any interior or exterior maintenance where suspended work must be performed.

Summit Anchor Company’s roof and wall anchor eyes are drop forged,

then quenched and tempered, resulting in strongest and most durable anchors on the market.

Here are some other reasons…

- Corrosion resistance Our anchors are completely hot-dipped galvanized with stainless bolts. Hollow Structural Sections (HSS) may be filled with molded urethane insulation to reduce thermal transfer and condensation and commonly in green construction. This option is recommended by Summit Anchor Company.

- OSHA/ANSI compliance Our anchors have been engineered and tested to comply with current OSHA regulations and ANSI/IWCA I-14.1 safety standard for fall arrest and suspended maintenance.

- Custom design for a variety of permanent attachments to reinforced concrete or structural steel. Summit roof and wall anchors can also be configured to fit virtually any structure.

- Anchors manufactured in the U.S.A.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Forging Process for Anchor Eyes

Minimum Loading Requirements for Anchors

- 5,000 lb. Ultimate load

- 2,500 lb. Test load

- 1,250 lb. Allowable load

Note: The structure to witch anchorages are attached must also support the reactionary forces imposed by anchorages and davit, etc.

(See Specifications for further detail.)

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.

Safety from the top down.

CLICK HERE to request a quote using our Design Assist Request.